Guangdong, China (Mainland)

DH

DH-AC-0011

acrylic (pmma) material

1.0mm~5.0mm

2440x1220mm 1830x1220mm, 2440x1220mm 1830x1220mm

plastic unbreakable mirror sheet in pmma material

Silver

1.2g/cm3

paint,PP backing,adhesive,3M adhesive,paper

Polished and protected by film or kraft

Extruded and vacuum plated

Home decoration / Furniture / Toy /display products etc.

Shaping easily and good durablity

SGS,REACH,PH,HE,Eco-Friendly

mirror finished plastic sheet in PMMA/acrylic material

Cleaning:

Acrylics are best cleaned using a soft cloth with fresh water to which a little detergent has been added.

Under no circumstances should methylated spirits nor solvent be used

Proprietary cleaning solutions should only be used if they are known to be compatible with acrylic sheet.

Abrasive cleaners of any kind should never be used.

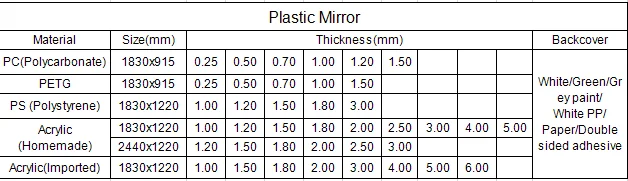

| Correlated Parameters | |

| Product name | Silver acrylic perspex mirror sheet, mirrored plastic sheets |

| Material | PMMA/acrylic |

| Process | Extruded / Film Laminating / Plating / Cutting (laser cutting,saw cutting,etc) / Silkscreen printing / Packing |

| Size | 2440x1220mm 1830x1220mm |

| Thickness | 1.0~5.0MM |

| Color | Silver |

| OEM/ODM | Yes and welcome |

| Plating | Aluminium |

| Backing | Adhesive / PP backing / Paper / Paint / 3M adhesive / Protective film etc. |

| Packing | Surface with protective film / Kraft / Carbard / Wooden pallet or as per request |

| Usage | Decoration / Furniture / Toy / Display panel / Bathroom / Road safety convex mirror / Cosmetics mirror / Advertisement etc. |

| Features | Eco-friendly / Mirror effect / Vivid colors / Scratch resistance / Acid and alkali corrosion resistance / Easy to clean / Waterproof / Moden designs etc. |

| Certificate | RoHs / EN-71 / ASTM / 9P /REACH 138 etc. |

| Sample time | 3-5 days after confirmation |

| Lead time | 10-25 days after sample approved / payment received (depend on order qty) |

| MOQ | 100 sheets / Negotiable |

| Shipping | By sea or air from Shenzhen port or Guangzhou port |

| By express : DHL / UPS / TNT / FedEx etc. | |

| Payment | By T/T, western union,L/C |

| 30% deposit and 70% balance before delivery |

| Products Show: |

| Packaging Details: | Covered with craft paper or PE film on double sides with pallet Bulk cargo packing: 2 tons per tray, use wooden pallets on bottom, with packaging film packages all around ensure transportation security. Full container load packing: 18-20 tons of a 20 foot container with 10 tray. |

|---|---|

| Delivery Detail: | 15 days |

| Packing: |

| Related Certificate: |

| Advantages: |

We provide "ONE-STOP" service of acrylic industries as we can finish the whole production process of making transparent sheet---vacuum plating---sawing---laser cutting---die cutting---shape copying---thermo forming by ourselves.

| FAQ: |

1. What is acrylic?

Acrylic Perspex is manufactured in a large range of colours and finishes. Clear acrylics also known as perspex are by far the most popular.A huge range of colours and tints are also available.

Acrylic is manufactured in the following types: 1)Extruded 2)Casting 3)Impact modified The main advantages include:

1)excellent weather resistance,unaffected by sun or salt spray temperature range of -30 to 160° degree F for continuous service.

2)Highly transparent sheet with a light transmission of 92%

3)Higher impact strength than glass

4)Excellent surface finish Easy to machine, fabricate and thermoform

5)Good resistance to dilute acids and alkalis

6)Half the weight of glass Impact resistant

7)Unaffected by sun or salt spray Temperature range of -30 to 160° F for continuous service

8)Good outdoor weathering

9)Fully recyclable Excellent surface hardness and durability

10)Food gradable Easy to clean and maintain

2. How to clean acrylic products?

Acrylics are best cleaned using a soft cloth with fresh water to which a little detergent has been added.Under no circumstances should methylated spirits nor solvent be used.Proprietary cleaning solutions should only be used if they are known to be compatible with acrylic sheet.Abrasive cleaners of any kind should never be used.

mirror finished plastic sheet in PMMA/acrylic material

Cleaning:

Acrylics are best cleaned using a soft cloth with fresh water to which a little detergent has been added.

Under no circumstances should methylated spirits nor solvent be used

Proprietary cleaning solutions should only be used if they are known to be compatible with acrylic sheet.

Abrasive cleaners of any kind should never be used.

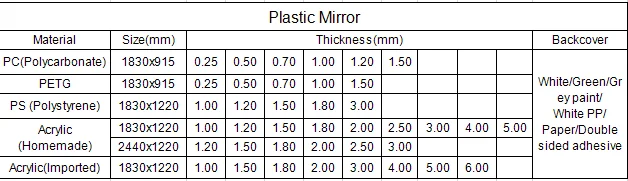

| Correlated Parameters | |

| Product name | Silver acrylic perspex mirror sheet, mirrored plastic sheets |

| Material | PMMA/acrylic |

| Process | Extruded / Film Laminating / Plating / Cutting (laser cutting,saw cutting,etc) / Silkscreen printing / Packing |

| Size | 2440x1220mm 1830x1220mm |

| Thickness | 1.0~5.0MM |

| Color | Silver |

| OEM/ODM | Yes and welcome |

| Plating | Aluminium |

| Backing | Adhesive / PP backing / Paper / Paint / 3M adhesive / Protective film etc. |

| Packing | Surface with protective film / Kraft / Carbard / Wooden pallet or as per request |

| Usage | Decoration / Furniture / Toy / Display panel / Bathroom / Road safety convex mirror / Cosmetics mirror / Advertisement etc. |

| Features | Eco-friendly / Mirror effect / Vivid colors / Scratch resistance / Acid and alkali corrosion resistance / Easy to clean / Waterproof / Moden designs etc. |

| Certificate | RoHs / EN-71 / ASTM / 9P /REACH 138 etc. |

| Sample time | 3-5 days after confirmation |

| Lead time | 10-25 days after sample approved / payment received (depend on order qty) |

| MOQ | 100 sheets / Negotiable |

| Shipping | By sea or air from Shenzhen port or Guangzhou port |

| By express : DHL / UPS / TNT / FedEx etc. | |

| Payment | By T/T, western union,L/C |

| 30% deposit and 70% balance before delivery |

| Products Show: |

| Packaging Details: | Covered with craft paper or PE film on double sides with pallet Bulk cargo packing: 2 tons per tray, use wooden pallets on bottom, with packaging film packages all around ensure transportation security. Full container load packing: 18-20 tons of a 20 foot container with 10 tray. |

|---|---|

| Delivery Detail: | 15 days |

| Packing: |

| Related Certificate: |

| Advantages: |

We provide "ONE-STOP" service of acrylic industries as we can finish the whole production process of making transparent sheet---vacuum plating---sawing---laser cutting---die cutting---shape copying---thermo forming by ourselves.

| FAQ: |

1. What is acrylic?

Acrylic Perspex is manufactured in a large range of colours and finishes. Clear acrylics also known as perspex are by far the most popular.A huge range of colours and tints are also available.

Acrylic is manufactured in the following types: 1)Extruded 2)Casting 3)Impact modified The main advantages include:

1)excellent weather resistance,unaffected by sun or salt spray temperature range of -30 to 160° degree F for continuous service.

2)Highly transparent sheet with a light transmission of 92%

3)Higher impact strength than glass

4)Excellent surface finish Easy to machine, fabricate and thermoform

5)Good resistance to dilute acids and alkalis

6)Half the weight of glass Impact resistant

7)Unaffected by sun or salt spray Temperature range of -30 to 160° F for continuous service

8)Good outdoor weathering

9)Fully recyclable Excellent surface hardness and durability

10)Food gradable Easy to clean and maintain

2. How to clean acrylic products?

Acrylics are best cleaned using a soft cloth with fresh water to which a little detergent has been added.Under no circumstances should methylated spirits nor solvent be used.Proprietary cleaning solutions should only be used if they are known to be compatible with acrylic sheet.Abrasive cleaners of any kind should never be used.