Views: 137 Author: Site Editor Publish Time: 2018-11-18 Origin: Site

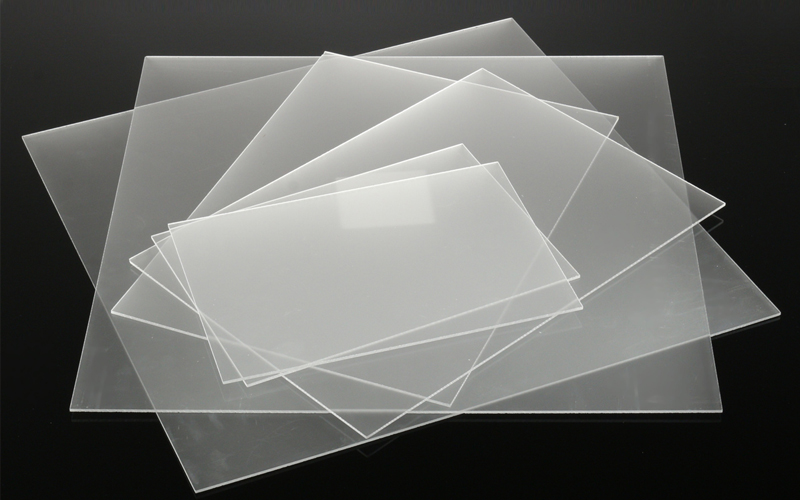

Poly(methyl methacrylate) (PMMA), also known as acrylic, acrylic (Acrylic) or plexiglass, Lucite (trade name), with high transparency, low price, easy to machine, etc. The advantage is the glass replacement material that is often used frequently.

1. The density of PMMA is lower than that of glass: the density of PMMA is about 1.15-1.19 g/cm3, which is half of glass (2.40-2.80 g/cm3) and 43% of metallic aluminum (belonging to light metal).

2. PMMA has high mechanical strength: PMMA sheet has a relative molecular mass of about 2 million, which is a long-chain polymer, and the molecular chain is very soft. Therefore, the strength of PMMA is relatively high, and it is resistant to stretching and impact. The ability is 7 to 18 times higher than ordinary glass. There is a heated and stretched plexiglass in which the molecular segments are arranged in a very orderly manner, resulting in a significant increase in the toughness of the material. The nail is nailed into the plexiglass, and even if the nail penetrates, no crack is generated. This kind of plexiglass will not break into pieces after being broken by bullets. Therefore, the stretched PMMA can be used as a bulletproof glass and also as a canopy on a military aircraft.

3. PMMA has a high light transmittance:

(1) Visible light: PMMA is currently the most excellent polymer transparent material, and its light transmittance is 92%, which is higher than that of glass.

(2) Ultraviolet light: Quartz can completely transmit ultraviolet light, but the price is high. Ordinary glass can only pass 0.6% of ultraviolet light. PMMA can effectively filter out ultraviolet light with a wavelength of less than 300 nm, but the effect of filtering between 300 nm and 400 nm is poor. Some manufacturers coat the PMMA surface to increase its effectiveness and properties of filtering out 300 nm to 400 nm UV light. On the other hand, PMMA has better stability than polycarbonate in the case of ultraviolet light.

(3) Infrared: PMMA allows infrared (IR) transmission of wavelengths less than 2800 nm. Longer wavelength IR, when less than 25,000 nm, can be substantially blocked. There is a special colored PMMA that allows specific wavelengths of IR to pass through while blocking visible light (for remote control or thermal sensing, etc.).

In the lighting industry, there is a common use of materials that occupy almost the majority of the lighting industry. This material is pmma sheet. Compared with other glass plastic products, it has many advantages.

First, the transparency of this material is high, and the color is more diversified compared with other similar materials, and it is more environmentally friendly, which greatly reduces the electricity consumption.

Second, the plasticity is strong and the shape is diversified to meet different needs, and the processing process is simpler.

Third, there is toughness, not easy to break, and there is no need to worry about safety.

The fourth is that its service life is longer, and it can be used for several more years than other materials.