Views: 6 Author: Site Editor Publish Time: 2021-05-17 Origin: Site

Acrylic vs Polycarbonate: Which One Is More Unbreakable?

We offen see the word of “unbreakable” used to describe acrylic mirror or polycarbontate mirror. Actually the term "unbreakable" is rather unscientific. If you hit acrylic or polycarbonate or any other material with enough energy, it will break. Nothing on this planet is actually unbreakable except in science fiction movies.

The material property most related to cracking is called "Impact Strength". The impact strength of Acrylic is 0.4 ft lbs/inch. Some people claim acrylic is roughly 10 times tougher than glass. This test for all materials is usually done at room temperature. Generally acrylic mirror is usable from -40 up to + 65 deg C (-40 up to 150 deg F). What happens is that the impact strength of the acrylic drops off at low temperatures, and below - 40F the material becomes very brittle. By comparison polycarbonate has an impact strength of 18 ft lbs/in which is about 45 times more than acrylic. However, its impact strength decreases below -20 deg C. The maximum use temperature of PC is higher than that of acrylic, but in practice that may not help much with mirrors because prolonged exposure above 65 C (150 F) is going to damage the back coating of the mirror so we would not recommend any higher use temperature for either polymer.

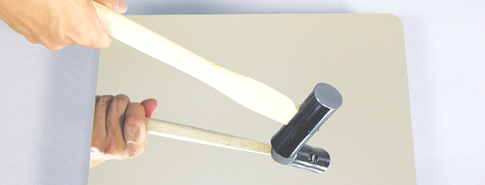

The impact strength of polycarbonate is roughly 20 times the impact strength of standard acrylic, which itself is already much higher impact strength and therefore unbreakable compared to glass. As you know, glass is actually very fragile, making it difficult to ship. Furthermore once glass is broken, the glass fragments are sharp and dangerous. The practical reality is that under all normal circumstances and even in many abnormal circumstances (such as in prisons), polycarbonate is very difficult to break. When you hit polycarbonate with a blunt object, the material will flex but not easily snap. It is a bit like the difference between a hard and rigid piece of wood which can snap versus a softer but pliable branch which bends but does not break. While bending it absorbs considerable energy. Think of the energy absorbed while bending a wooden bow, which then shoots the arrow when released. Polycarbonate is like the flexible branch which flexes but does not break. Acrylic is more like the harder and more rigid wood which is strong but will snap if flexed too far. As a result of this, polycarbonate is much softer than acrylic and therefore polycarbonate is much more easily scratched than acrylic. Of course you can add scratch resistant coatings to acrylic or polycarbonate.

To summarize, acrylic is much more impact resistant than glass, and polycarbonate is much more impact resistant than acrylic. Neither acrylic nor polycarbonate produce dangerous fragments when broken. Compared to polycarbonate, acrylic is typically more scratch resistant, but less impact resistant.