| Availability: | |

|---|---|

| Quantity: | |

1. Vacuum plating, laser cutting, sawing machine,die cutting

2. Safety, shatterproof,

3. Customized design

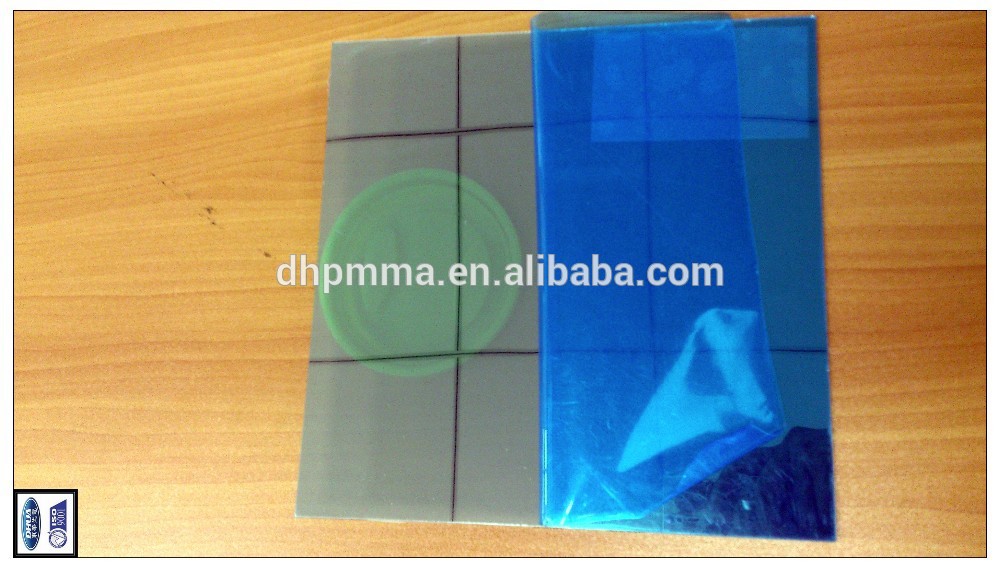

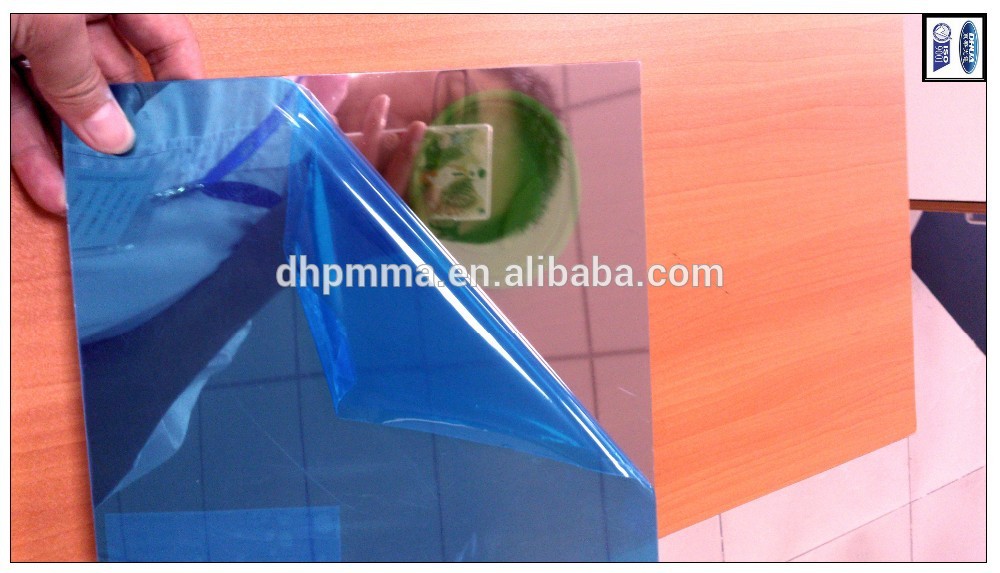

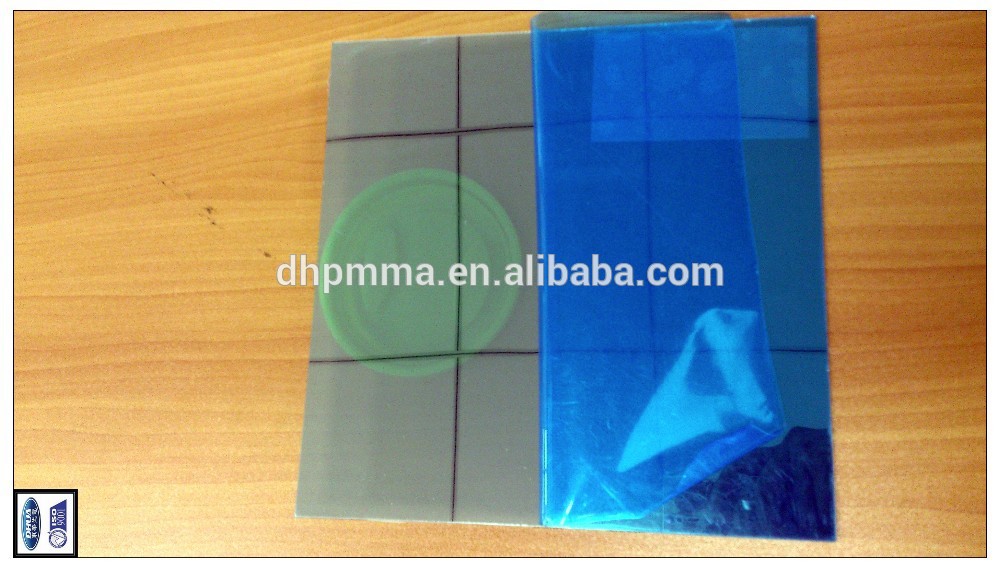

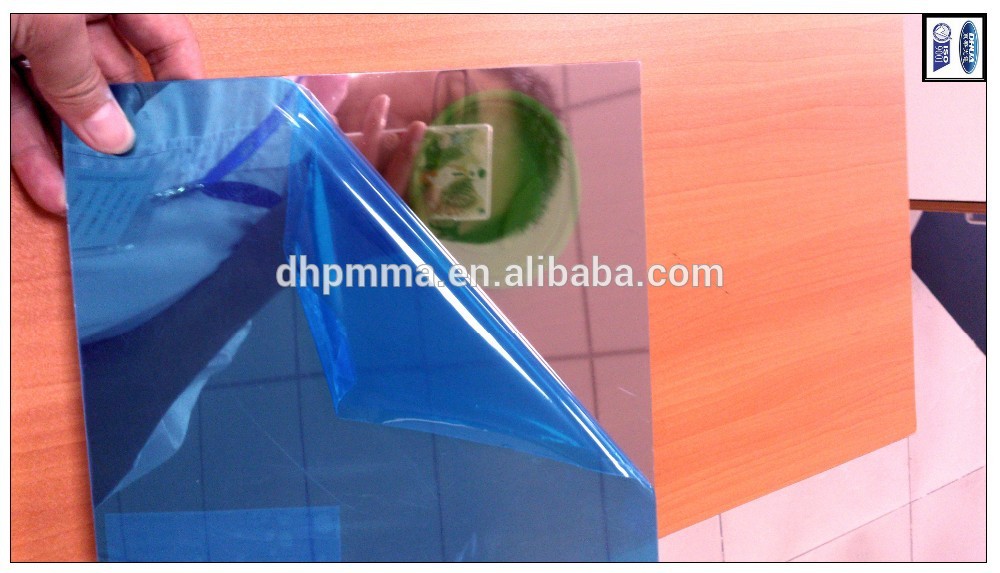

plastic translucent mirror shatterproof ,unbreakable semi-permeable acrylic mirror

double side is reflective,ligt can go through so you can see from one side to the other side

Plexiglass Acrylic see through Mirror

They are versatile plastic material that can be used in numerous applications and has great impact strength yet is light weight with exceptional optical quality. plastic mirror is easy to work with. It can be sawed, drilled, routed, glued, painted, decorated, silk-screened, and formed.

In addition to being light weight, plastic mirror is ten times stronger than glass. It is an excellent choice when safety is a consideration. Unlike regular glass, plastic mirror does not shatter into small sharp pieces when broken.

1. To reflects light throughout the bedroom or bathroom

2. Can be used to brighten up your home and bring some life of your walls

3. Customized is available

4. OEM & ODM are acceptable

Cleaning:

Acrylics are best cleaned using a soft cloth with fresh water to which a little detergent has been added.

Under no circumstances should methylated spirits nor solvent be used.

Proprietary cleaning solutions should only be used if they are known to be compatible with acrylic sheet.

Abrasive cleaners of any kind should never be used.

| Packaging Details: | Covered with craft paper or PE film on double sides with pallet Bulk cargo packing: 2 tons per tray, use wooden pallets on bottom, with packaging film packages all around ensure transportation security. Full container load packing: 18-20 tons of a 20 foot container with 10 tray. |

|---|---|

| Delivery Detail: | 15 days |

| Packing: |

| Related Certificate: |

| Advantages: |

We provide "ONE-STOP" service of acrylic industries as we can finish the whole production process of making transparent sheet---vacuum plating---sawing---laser cutting---die cutting---shape copying---thermo forming by ourselves.

Extruted Clear Acrylic Sheet / Panel

Vacuum plating Mirrors: PMMA / PETG / PC / PS / PVC Mirrors

Peel & Stick Mirror Decals for Home and Garden Decoration

Acrylic Convex Mirrors for Traffic Security

Baby Safe Mirrors for Toys & Cars

Anti-fog shower shaving mirror / Anti-fog face shield

| FAQ: |

1. What is acrylic?

Acrylic Perspex is manufactured in a large range of colours and finishes. Clear acrylics also known as perspex are by far the most popular.A huge range of colours and tints are also available.

Acrylic is manufactured in the following types: 1)Extruded 2)Casting 3)Impact modified The main advantages include:

1)excellent weather resistance,unaffected by sun or salt spray temperature range of -30 to 160° degree F for continuous service.

2)Highly transparent sheet with a light transmission of 92%

3)Higher impact strength than glass

4)Excellent surface finish Easy to machine, fabricate and thermoform

5)Good resistance to dilute acids and alkalis

6)Half the weight of glass Impact resistant

7)Unaffected by sun or salt spray Temperature range of -30 to 160° F for continuous service

8)Good outdoor weathering

9)Fully recyclable Excellent surface hardness and durability

10)Food gradable Easy to clean and maintain

2. How to clean acrylic products?

Acrylics are best cleaned using a soft cloth with fresh water to which a little detergent has been added.Under no circumstances should methylated spirits nor solvent be used.Proprietary cleaning solutions should only be used if they are known to be compatible with acrylic sheet.Abrasive cleaners of any kind should never be used.

1. Vacuum plating, laser cutting, sawing machine,die cutting

2. Safety, shatterproof,

3. Customized design

plastic translucent mirror shatterproof ,unbreakable semi-permeable acrylic mirror

double side is reflective,ligt can go through so you can see from one side to the other side

Plexiglass Acrylic see through Mirror

They are versatile plastic material that can be used in numerous applications and has great impact strength yet is light weight with exceptional optical quality. plastic mirror is easy to work with. It can be sawed, drilled, routed, glued, painted, decorated, silk-screened, and formed.

In addition to being light weight, plastic mirror is ten times stronger than glass. It is an excellent choice when safety is a consideration. Unlike regular glass, plastic mirror does not shatter into small sharp pieces when broken.

1. To reflects light throughout the bedroom or bathroom

2. Can be used to brighten up your home and bring some life of your walls

3. Customized is available

4. OEM & ODM are acceptable

Cleaning:

Acrylics are best cleaned using a soft cloth with fresh water to which a little detergent has been added.

Under no circumstances should methylated spirits nor solvent be used.

Proprietary cleaning solutions should only be used if they are known to be compatible with acrylic sheet.

Abrasive cleaners of any kind should never be used.

| Packaging Details: | Covered with craft paper or PE film on double sides with pallet Bulk cargo packing: 2 tons per tray, use wooden pallets on bottom, with packaging film packages all around ensure transportation security. Full container load packing: 18-20 tons of a 20 foot container with 10 tray. |

|---|---|

| Delivery Detail: | 15 days |

| Packing: |

| Related Certificate: |

| Advantages: |

We provide "ONE-STOP" service of acrylic industries as we can finish the whole production process of making transparent sheet---vacuum plating---sawing---laser cutting---die cutting---shape copying---thermo forming by ourselves.

Extruted Clear Acrylic Sheet / Panel

Vacuum plating Mirrors: PMMA / PETG / PC / PS / PVC Mirrors

Peel & Stick Mirror Decals for Home and Garden Decoration

Acrylic Convex Mirrors for Traffic Security

Baby Safe Mirrors for Toys & Cars

Anti-fog shower shaving mirror / Anti-fog face shield

| FAQ: |

1. What is acrylic?

Acrylic Perspex is manufactured in a large range of colours and finishes. Clear acrylics also known as perspex are by far the most popular.A huge range of colours and tints are also available.

Acrylic is manufactured in the following types: 1)Extruded 2)Casting 3)Impact modified The main advantages include:

1)excellent weather resistance,unaffected by sun or salt spray temperature range of -30 to 160° degree F for continuous service.

2)Highly transparent sheet with a light transmission of 92%

3)Higher impact strength than glass

4)Excellent surface finish Easy to machine, fabricate and thermoform

5)Good resistance to dilute acids and alkalis

6)Half the weight of glass Impact resistant

7)Unaffected by sun or salt spray Temperature range of -30 to 160° F for continuous service

8)Good outdoor weathering

9)Fully recyclable Excellent surface hardness and durability

10)Food gradable Easy to clean and maintain

2. How to clean acrylic products?

Acrylics are best cleaned using a soft cloth with fresh water to which a little detergent has been added.Under no circumstances should methylated spirits nor solvent be used.Proprietary cleaning solutions should only be used if they are known to be compatible with acrylic sheet.Abrasive cleaners of any kind should never be used.