Views: 106 Author: Site Editor Publish Time: 2018-10-01 Origin: Site

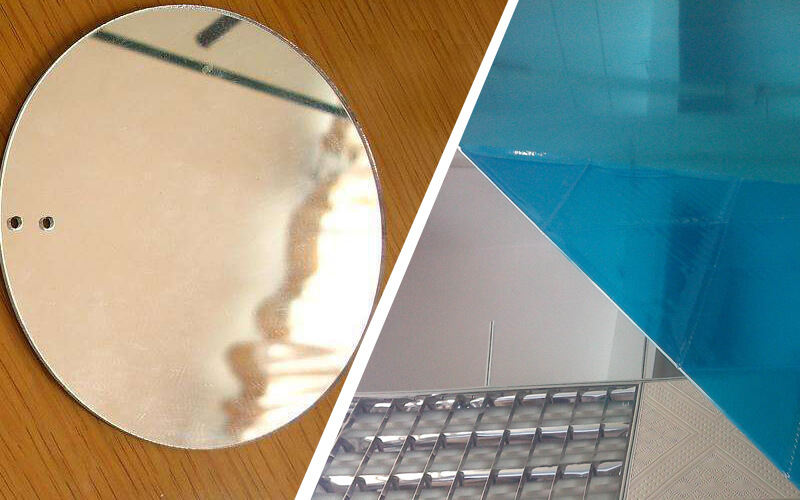

Acrylic mirror has the advantages of light weight, low cost and easy molding. Its forming methods include casting, injection molding, machining, and acrylic thermoforming. In particular, injection molding can be mass-produced, with simple process and low cost. Therefore, its application is becoming more and more extensive, and it is widely used in instrumentation parts, automobile lamps, optical lenses, transparent pipes, etc.

PC mirror, the general resin lens is a thermosetting material, that is, the raw material is liquid, and after heating, a solid lens is formed. The PC film is also called "space film" and "cosmic film". The chemical name is polycarbonate and it is a thermoplastic material. That is, the raw material is solid, and after being heated, it is shaped into a lens, so that the finished lens is deformed by excessive heat and is not suitable for high humidity and heat. PC lens has strong toughness and is not broken (2cm can be used for bulletproof glass), so it is also called safety lens. With a specific gravity of only 2 grams per cubic centimeter, it is the lightest material currently used in lenses.