Views: 7 Author: Site Editor Publish Time: 2018-09-28 Origin: Site

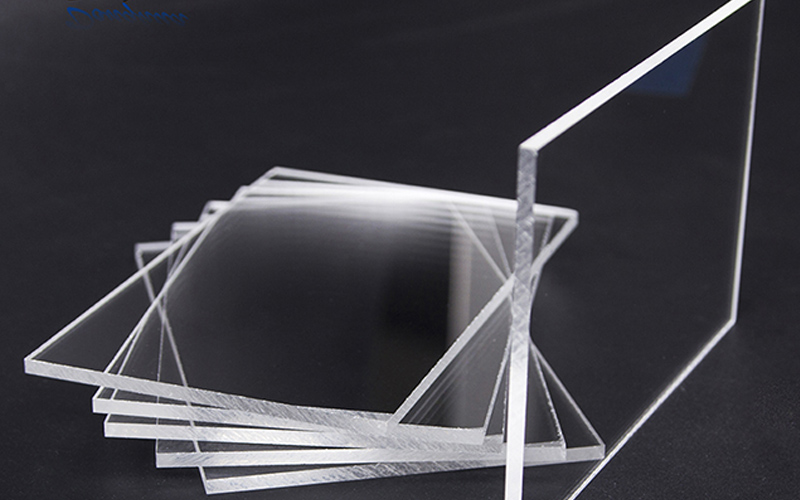

With the rise of acrylic sheet materials, most of our house renovations now choose acrylic sheets, so why are acrylic sheets so popular? Let's learn about acrylic sheets together.

1.Expansion rate after water absorption This indicator can be regarded as qualified within 3%. Otherwise, the acrylic sheet will be deformed when it is wet, or when the humidity is relatively high and the surrounding seal is not tight, which will affect the normal use.

2.Formaldehyde content This is a key indicator of whether the product we choose is harmful to the body, but it is easily overlooked by consumers. According to European standards, the formaldehyde content per 100 grams of acrylic sheet should not exceed 9 mg, if more than 9 mg is a substandard product.

3.Acrylic plate thickness At present, the thickness of the acrylic sheet on the market is generally 6 to 12 mm, and the thickness should be thicker when selected. The thicker the thickness, the longer the service life, but at the same time the actual needs of the family must be considered. The assembly effect can be assembled with two acrylic plates, to see if it is neat and rigorous after assembly. Acrylic sheet weight The weight of an acrylic sheet depends mainly on the density of its substrate. The substrate determines the stability of the acrylic sheet and the impact resistance. Therefore, the better the substrate, the higher the density, and the heavier the acrylic sheet.

4, wear resistance This is an important indicator for measuring the quality of composite acrylic sheets. Objectively speaking, the higher the wear resistance number, the longer the acrylic sheet should be used, but the wear resistance value is not the only standard to measure the service life of the acrylic sheet. Under normal circumstances, the wear resistance of the composite acrylic sheet reaches 10,000 rpm, and the product with less than 10,000 rpm may have different degrees of wear after 1-3 years of use.

5. Formal certificate and inspection report When consumers choose acrylic sheets, they must find out whether the relevant certificates and quality inspection reports are available to the merchants. The relevant certificates generally include the acrylic board certificate of origin, the European Composite Acrylic Board Association (EPLF) certificate, the ISO9001 quality certificate, the ISO14001 environmental certificate, and other related quality certificates.

6, environmental performance The problem that consumers are generally concerned about is the environmental performance of acrylic sheets. The first consideration when choosing an acrylic sheet is the environmental friendliness of the product, followed by the other properties of the product, as well as the price. You can check whether the acrylic sheet is an environmentally friendly product by checking whether there is a relevant green certificate.